The term AI is is often seen as a universal tool for many areas, when in fact it encompasses discrete areas with different strengths and weaknesses, which are often lumped together und the umbrella of “AI”.

Logistics is ideal for the implementation of artificial intelligence

This statement can be found in trade journals and also in our logistics wiki in the article ‘Artificial Intelligence (AI) and logistics’. In the defense of her master thesis Sina Hill takes a closer look at this question with the support of Prof. Dr. Frank Thomas. A definition for Artificial Intelligence from the task perspective is “the ability of a system to perform tasks that normally require human intelligence”.

The largest application areas for this, with which each of us – who own a smartphone – has already had contact: pattern recognition and prediction. Be it route planning based on real-time data via Google Maps or, in the latest smartphone generation, the automatic optimization of an image.

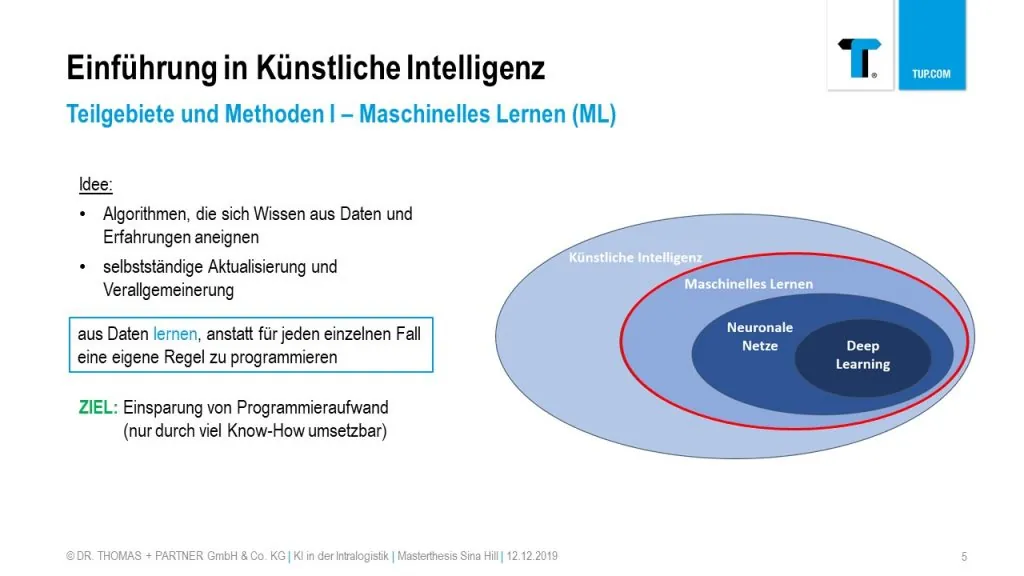

Machine Learning

Machine learning refers to algorithms that acquire knowledge from data and experience in dealing with defined scenarios and can thus adapt themselves to similar scenarios and derive generalizations from the ‘experienced’ events. The advantage is that not every special case has to be taken into account and be given its own rules.

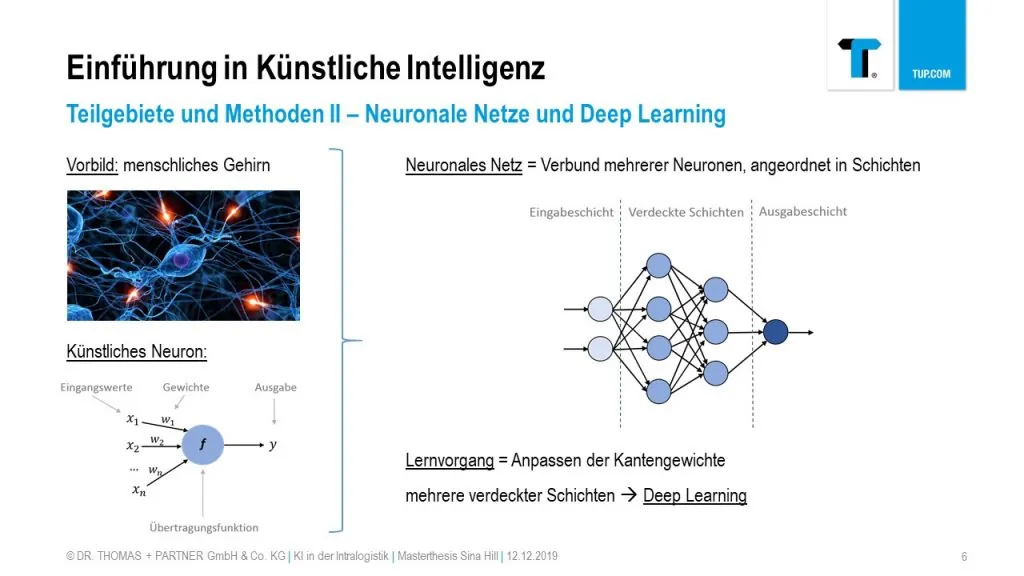

Neural Networks

The model for neural networks is the network of cells found in the human brain, for example. Here the rule is “the more the better”, which should not come as a big surprise. For this purpose, artificial neurons have been developed, in the core of which a certain transfer function is stored and acts on the input values so that in the end only one value is passed on. These basic building blocks are arranged in layers, which are connected with each other. The connections transmit a weighting of the transmitted value, and this is the basis for the learning process of the network: The weightings between the connections are dynamically adapted. Since only the output layer is visible in these constructs, the ones behind it are called ‘Hidden Layer’. If several layers are used, the term ‘Deep Learning’ is used, because the path to the result may not be traceable anymore for human beings.

What are the appropriate clusters in intralogistics

From Sina Hill’s perspective there are five large fields: The analysis of Big Data, the optical recognition of objects in the warehouse, the optimization of processes, the prognosis of object movements and human-machine interaction. The aim of the master thesis was to evaluate the benefits of machine learning, neural networks and deep learning for these fields of intralogistics.

Optical recognition

The task here is to identify objects and their condition optically. Especially in large warehouses with heterogeneous articles a high optimization potential in quality control and identification of the objects on the materials handling technology can be realized.

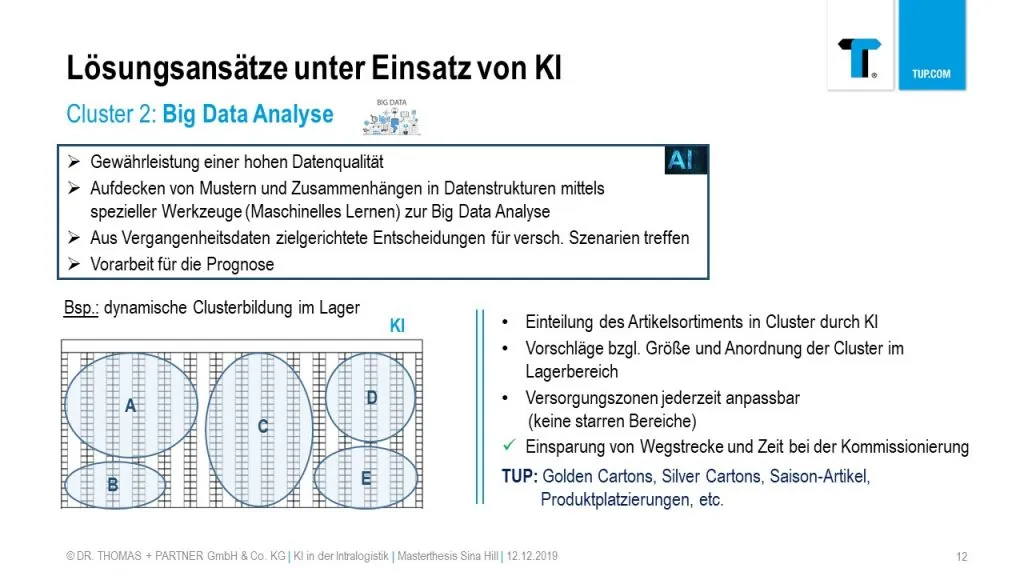

Big data analysis

The goal of the analysis is to prepare and structure past data sets and identify interconnections. The components for intralogistics here are master data management and storage allocation. The advantage of AI, in this case, is that all methods depend on large amounts of data to reach their full potential and therefore can handle large amounts of it very well, where other methods fail or lose efficiency. Thus, patterns in goods movements and better storage space allocation can be achieved, which otherwise could only be identified by a high research effort.

Forecast

Forecasting market demand, staffing requirements and possible returns based on historical data is a field in which great hope is placed in the performance of AI solutions. Another scenario here, which every user of modern route planning has already experienced, is the identification of potentially more efficient routes and transit times. This increases the potential of forecasts, as more and more complex values can be considered. Especially in the fashion industry, the forecast of returns is of high relevance, because it may help to avoid unsustainable strategies such as the disposal of returns.

Optimization

Here, algorithmic solver solutions are already used to ensure the ideal path of the article with a balanced utilization of the available resources in the warehouse. The higher the complexity of this decision and the more data available here, the greater the potential benefit of Artificial Intelligence through forecasting or faster decisions, even in emerging situations.

Such problems are negotiated by the discipline ‘Operations Research’, which follows procedures such as linear optimization. The potential here lies in the fact that not all functions have to be computed, but rather forecasts can be generated via AI. However, the prerequisite for this is expert knowledge within the company and a very good database. Otherwise the principle of ‘garbage in, garbage out’ applies.

Solver solutions such as those used by TUP are often referred to as AI. To avoid misunderstandings, TUP clearly assigns this tool to Operation Research.

Human-Machine Interaction

In this interaction, human error should be avoided and the interaction of the two should be safe. The central points here are the control of the picking process and the formation of the most efficient shipping units. The problem here: AI works best with large amounts of data, but picking should be made as simple as possible to avoid potential errors and increase efficiency. One possible use case is AI-supported scanning and recognition of the items in a shipment, so that the items no longer need to be scanned by the employee, who can then concentrate fully on picking.

Overview

Artificial intelligence offers the highest added value potential in everything that concerns decision making and thus moves into the domain of human decisions. More complex and potentially better decisions can be made in real-time at both the strategic and operational levels of the warehouse as new insights and more robust forecasts are gained from complex data.

At the level of manual activities in intralogistics, AI can mainly provide route-finding and automated object identification. A disadvantage of neural networks is also that the path to the solution may not be traceable, but achieving it still consumes many resources in implementation and deployment. This is a difficult situation in the rapidly changing world of intralogistics, where the question ‘How does it work?’ involves large sums of money.

Further recommendations: