TUP.WMS

Uncompromising individuality

When processes become large and complex, we shine. For over 40 years, we have been developing customized solutions where workflows need to be fast, safe and efficient. Because in intralogistics, the margin hinges on an eye for detail in the right place at the right time. Our warehouse management system grows with your challenges – whether it’s larger storage areas, a higher degree of automation or new business opportunities. Our credo “Software follows function” guides us to achieve your goals.

Software follows function

We love “simple but smart”

We love the daily challenge of finding simple, efficient solutions to complex challenges and utilizing all the opportunities for your warehouse management. To do this, we take a very close look at new trends and extract the things that work. Because at the end of the day, your processes set the pace. Comprehensive parameterization and design freedom for processes and input masks offer directly implementable benefits.

Holistic intralogistics

Intralogistics begins and ends for us at the site gate

For us, intralogistics is not just conveyor belts, forklifts and high-bay warehouses. For us, intralogistics means the entirety of your processes and data. It begins when the truck passes through your gate and ends when it leaves. This is how we create a holistic, transparent picture of your intralogistics, from goods receipt to goods issue.

Data quality - data flow - data utilization

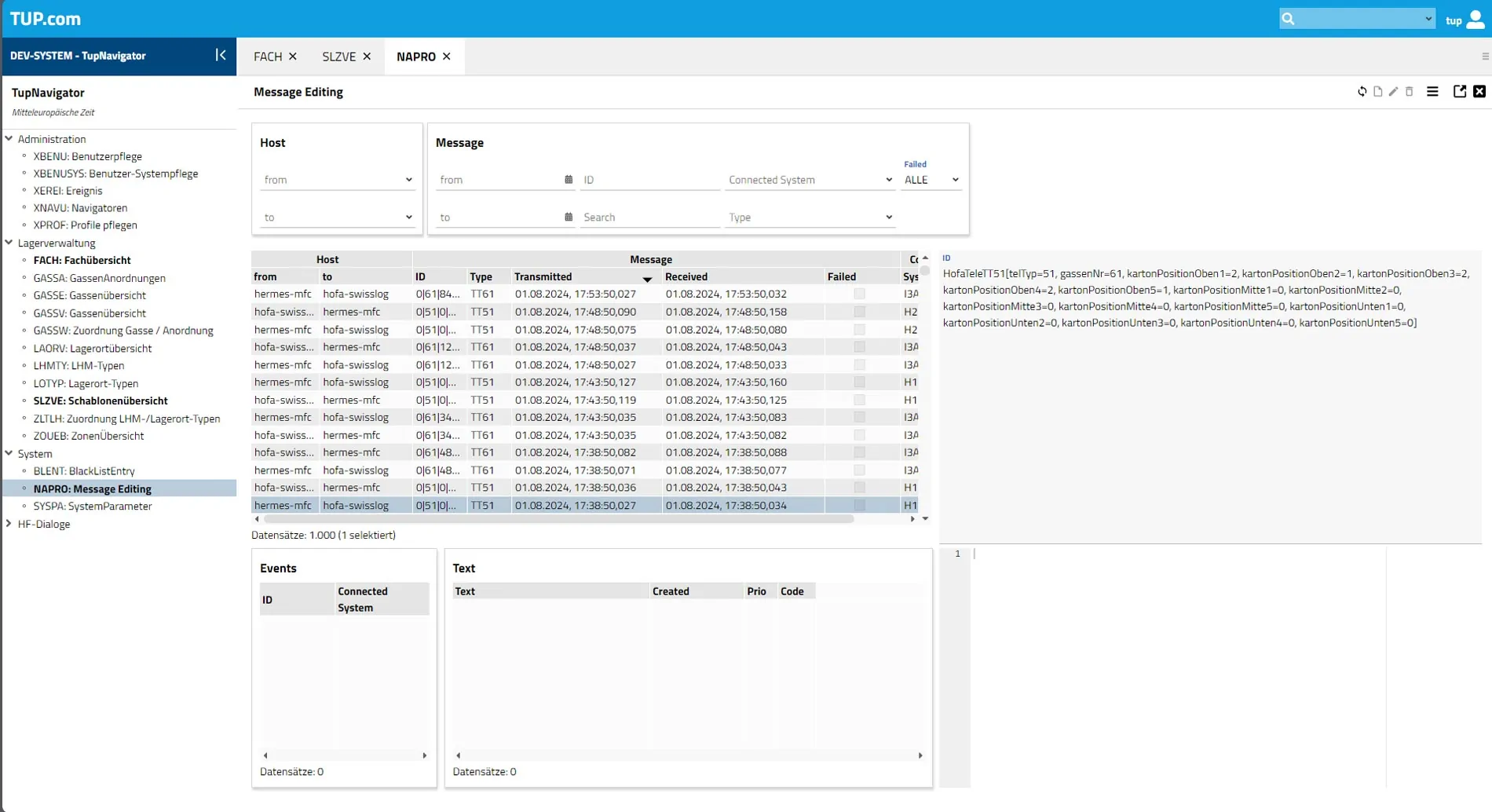

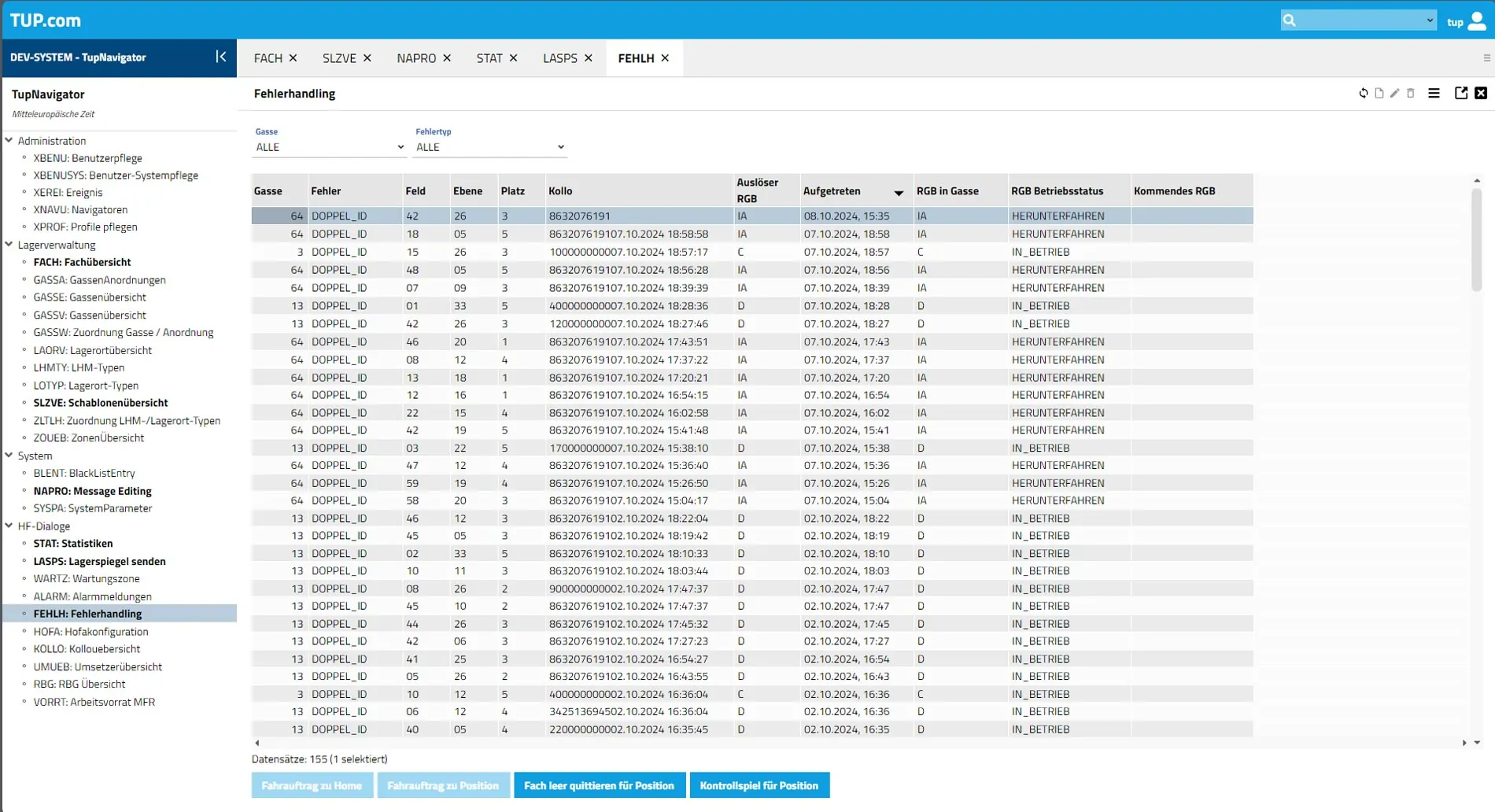

We know that a warehouse management system is the decisive information source

The Warehouse Management System is the ideal information platform for upstream and downstream systems. This is where all the threads come together. We collect granular data for each work step and prepare it for your dashboards and ERP systems. We enrich the information from the material flow and PLC level with valuable information so that you always have an overview of all the “what”, “how much”, “why”, “when” and “where”.

Excellent usability

No ready-made dashboards, just yours

Data availability is one thing, data readability is another. We know that the user-friendly preparation and visualization of data is the key to efficient and, above all, resilient processes. From multi-language capability to individually parameterized dashboards and smart data, we transform your vast amounts of data within the warehouse management system into operational added value.

Individual and resilient

Complete freedom

No matter which materials handling technology, no matter which or how many material flow controllers, no matter which ERP, we talk to each and everyone. With us, you are not restricted to a walled garden, but are free to choose the best provider for the respective purpose. From A for AWS to O for On Premise. We have a comprehensive range of interfaces and have been at the cutting edge of new developments and standards in warehouse management for over 40 years.

TUP.WMS: customizable, flexible, highly performant

Warehouse management software straight to the point

- Palletization and loading via MDT functions

- Loading scanning and photographic documentation of the load securing

- Mapping of all outgoing goods processes

- Outgoing goods control, palletization, loading

- Customs clearance

- Storage processes

- Outward transfer of the shipping packages at the shipping sorter to the corresponding shipping relations

- Cross-belt sorter

- Dynamic management of the automatic carton warehouses

- Station supply with incoming cartons and empty bins optimized for filling level

- Tilt-tray sorter

- Control of the shipping packages to the closing lines, taking into account the type of box and the occupancy of the line

- Control of flat/hanging goods – hanging bag conveyor system

- Control of multi-level shelving systems

- Packaging lines and closing stations

- Supply of the bag loading stations with picked containers

- Mapping of all storage processes

- Import processing and management of bonded goods

- Fully automatic entry of goods receipts with the generation of master data in real time

- Mapping of all incoming goods processes

- Incoming goods – notified SSCC collection

- Individual incoming goods management of suppliers and own production

- Quality management processes

- Dialog-supported returns and processing workflows

- Returns stock utilization for deliveries

- Returns handling on an individual item basis

- Returns processes

- Inventory by material or storage location

- Permanent inventory

- Sequential test (inventory)

- SAP connection (MM, SD, QM, BW)

- Connection to multiple hosts with different clients

- Connection of your shipping system

- Documents – delivery notes, labels, etc.

- Inventory management

- Document management system

- E-mail messaging system

- Ergonomic workplace design

- Labeler control

- Device management

- Individually configured warehouse management systems for different sites

- Integration of client companies with different order structures

- Multilingual dialog system

- Multi-warehouse system

- Smart Mobile Logistics (SML with image display) as the core element of all logistics processes

- Transport management

- Central system maintenance

- External warehouse connection

- Automatic replenishment trigger

- Putaway via mobile device

- Flexible assignment of storage locations

- Integrated bulky goods handling

- Intelligent storage spaces

- KLT box and tray management system

- Storage location optimization

- Storage location management with real dimensions

- Storage and optimization processes

- Long goods storage processing

- MDT-supported sub-process control (handheld & forklift terminals)

- Optimized storage location search for heterogeneous warehouse goods

- Configurable flow channel management

- Forklift control system

- System-controlled storage bin allocation

- Relocation / reallocation / compression

- Debiting of consumed items in production

- Connection of assembly – just-in-time/just-in-sequence assembly supply

- Order type-related picking processes

- Order management

- Order management with order split and order consolidation

- Batch management

- Paperless online picking

- Provision of inventory for external production

- Cross-docking and optimized cross-dock processes

- Differentiated picking

- Dynamic batch creation

- Production line testing processes

- Integration of picking warehouse for assembly supply and shipping

- Picking processes

- Picking

- Picking on stacker crane in the aisle

- Picking according to FIFO

- Empty crate management system

- Delivery processes

- Person-to-goods processing

- Manual sorter picking

- Online invoice printing

- Online tour generation

- Packaging material structure and supply system

- Packing station functions for bags supplied by the bag sorter

- Packing processes

- Pick-by-Light

- Pick-by-Voice

- Pick-Pack order picking

- Production supply

- Route optimization

- Forming processes for consolidated packages

- Target package forming processes

- Special picking of fast-moving items

- Comprehensive batch creation algorithms, including consideration of returns in the dynamic buffer

- Packaging

- Tubing management system

- Goods-to-person picking

- Route-optimized picking

Success Story

Breuninger combines three locations in a state-of-the-art multi-channel warehouse and relies on TUP.WMS

Previously, Breuninger handled store deliveries and direct customer deliveries via three logistics locations with an explicit focus on either pure B2B or B2C. A new, large distribution center in Sachsenheim was to combine the previously separate locations. Both delivery variants were to be handled under the umbrella of a process-optimized multi-channel warehouse. Due to the demanding, individual processes, Breuninger needed a modular, adaptive and customized warehouse management software.

Success Story

TUP implemented two large-scale projects for the bicycle manufacturer Canyon

A new production site with optimized intralogistics was created in a short space of time, laying the foundations for state-of-the-art manufacturing and the associated growth potential. As a follow-up project, a cross-location symbiosis of production logistics and warehouse logistics was realized by TUP.

Software follows function

Intelligent warehouse management through individual adaptation to your requirements

With TUP.WMS, you can control your material and information flows from manually oriented to highly automated warehouses. Our goal is to further expand the potential of your intralogistics processes as a competitive advantage through software solutions.

Whether automotive, pharmaceuticals, e-commerce, retail, start-ups or international corporations, our software solution supports the growth of our project partners through flexible parameterization and the simple integration of all necessary interfaces.

Thanks to our market experience since 1980, we have a broad repertoire of market-proven best-practice modules that we can apply to your individual requirements and functions. Increase the efficiency of your intralogistics processes across the entire flow of goods through transparency of all warehouse movements on the basis of comprehensive control station functions and via a flexible combination of different picking processes.

Together with our project partners, we develop more than just a warehouse management system based on TUP.WMS – we develop exactly the solution that is needed. This results in powerful and stable systems that successfully meet the requirements of the present and the future.

TUP.WMS: Individual, flexible, highly performant

The warehouse management software for the highest standards

TUP.WMS is the heart of the TUP portfolio and offers best practices for all processes, from goods receipt to storage and picking to goods issue. Discover the benefits for your intralogistics by navigating to the other features using the arrows.

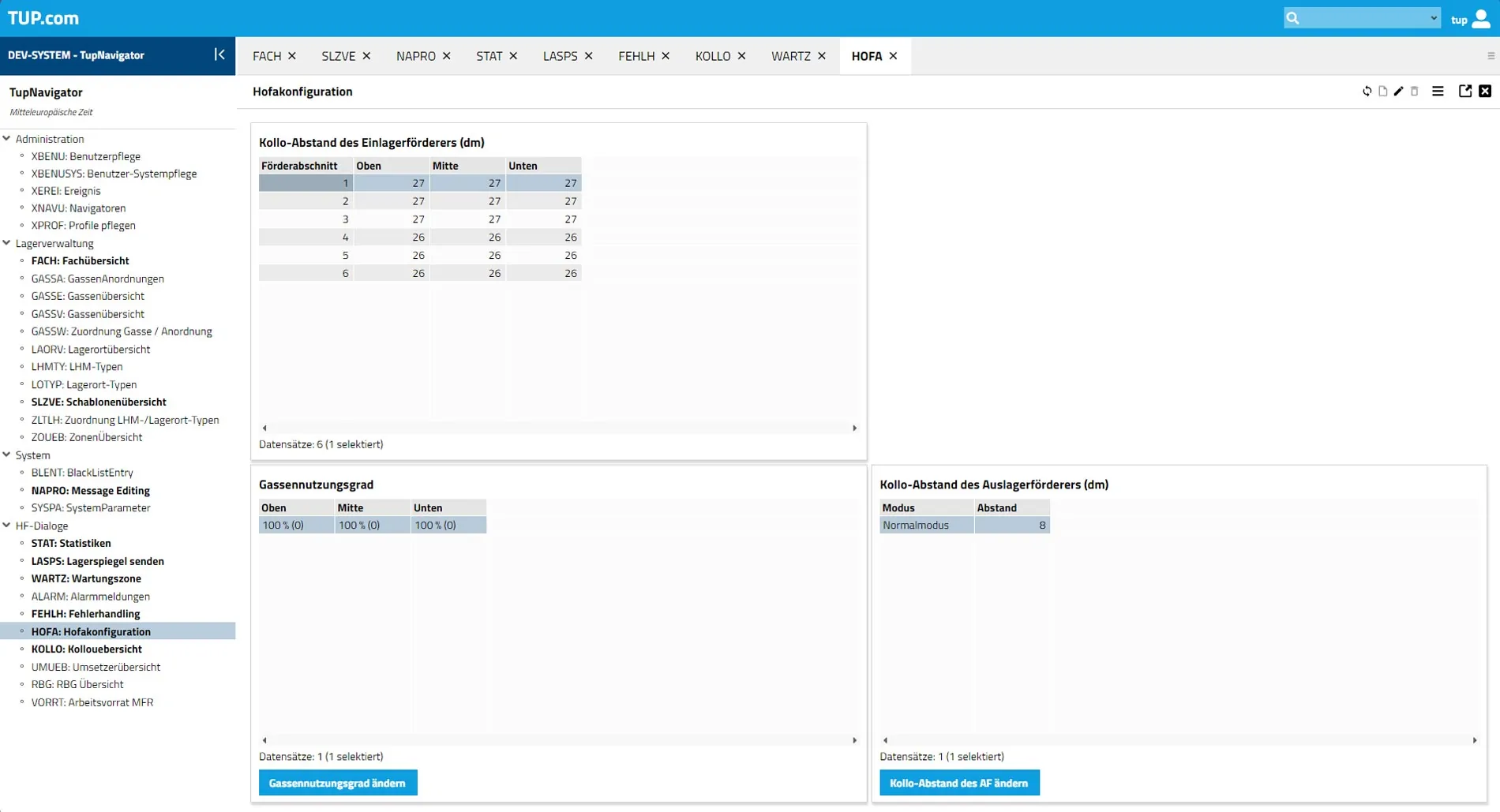

Boost efficiency in your warehouse

Unused storage space wastes potential, while insufficient storage space reduces throughput and jeopardizes logistics goals. Therefore, the choice of warehouse size and strategy is crucial to your success. TUP.WMS offers you the opportunity to design your warehouse according to your needs.

Warehouse configuration options

Control your inventory management based on the fixed bin location system, chaotic management or flexible bin allocation by your employees. TUP.WMS supports manual and automatic storage and retrieval, ABC warehousing and single-batch warehousing. Use flexible replenishment strategies in your picking, such as Kanban outsourcing, preemptive or statistical replenishment. Define criteria for quality changes or for the implementation of quality blocks. Single- or double-deep pallet storage is also integrated.

All common storage types, such as shelf storage, pallet storage, high-bay storage or automatic bin storage systems (AS/RS), are supported. In addition, the warehouse management software can control paternoster lifts, automatic carton warehouses with optimized routes and many other solutions.

Warehousing strategies

You can use statuses to track stock transfers between warehouses, locations, bins and containers in the system, even when parts of a pallet are consolidated or transferred. If required, TUP.WMS can also automatically generate stock transfers to optimize storage locations in both manual and automatic warehouses.

Blocks

Blocks can be defined based on the location parameter, such as site, storage location, storage zone, storage bin. In addition, object-based properties can be used, such as load carrier, item, batch, serial number, delivery, order or order item.

Stocktaking

TUP.WMS supports stocktaking in the entire warehouse, in a specific area of the warehouse or in a storage bin. The process can be limited to a single item or a specific period of time. If necessary, the system blocks the items to be included in the stocktaking. Documentation is provided via count and difference lists or a permanent automated stocktaking.

Pattern recognition

TUP systems enable the fast, easy and targeted integration of artificial intelligence for intralogistics TUP.AI. With the help of the application-oriented machine learning models, complex relationships in the warehouse can be decoded and remarkable optimization rates can be achieved.

Verwaltung des Wareneingangs

Der Wareneingang steht am Anfang der Prozesskette im Lager. Die hier erfassten Daten sind die Grundlage für die weiteren Abläufe. Ihre Richtigkeit bestimmt daher die Qualität aller Folgeprozesse.

Datenerfassung

Alle relevanten Informationen werden in der notwendigen Qualität erfasst: Spediteure, Fahrzeugdaten, Lieferdaten und -zeiten und vieles mehr. Die Art der Erfassung kann bis ins Detail definiert werden: Sendungserfassung mit oder ohne Avis, die Erfassung von Serien/Chargennummern, Verfallsdaten oder die Zuordnung zu Einzel-, Teil- oder Gesamtlieferungen und mehr sind möglich. Die Daten können an I-Punkten automatisch oder manuell erfasst werden.

Monitoring und Steuerung

Über das Avis- und Liefermonitoring werden Liefertermin, Mengen, Waren, Qualität, Unter- oder Überschreitungen überwacht Das vereinfacht die Qualitätssicherung und Plausibilitätsprüfung in der Klärfallabwicklung.

Die Steuerung erfolgt durch die automatische oder manuelle Zielvergabe mit verschiedenen flexiblen und parametrierbaren Einlagerstrategien. Folgende Parameter finden dabei Anwendung: Logistische Stammdaten, physikalische Parameter der Lagerplätze, Zuordung der Artikel zu Lagergruppen oder -zonen auf Basis von Priorisierungen wie ABC-Verteilung oder im Artikelstamm definierter Lagerstruktur. Für eine mögliche granulare Kontrolle können Bereiche als Puffer oder mit einer Einlagersperre gekennzeichnet werden.

Das TUP.WMS generiert die Transportaufträge für den Materialflussrechner oder auch manuelle Prozess-Schritte. Es unterstützt über verschiedene Schnittstellen alle Prozesse. Interne und externe Retouren werden ebenfalls über die Prozesssteuerung abgedeckt.

Labels und Dokumentation

Wareneingangsbelege jeglicher Art können automatisch oder manuell ausgedruckt werden: LE-, LTG-Labels, Barcodes, Einlagerhilfen oder Zollmeldungen.

Kommissionierungsanforderungen

Die Kommissionierung ist das Herzstück Ihres Distributionszentrums. Deshalb wollen wir zuerst Ihre Strukturen und Anforderungen verstehen, bevor wir Ihr passgenaues Kommissioniersystem umsetzen. Die Effizienz dieses Systems beeinflusst maßgeblich Reaktionszeit und Kosten, die zentralen Kennzahlen für den Erfolg Ihrer Intralogistik. Wegeoptimierung ist daher oberstes Gebot, da die Kommissionierung viele manuelle Vorgänge hat.

Unterstützte Kommissionierarten

Ein- bis dreistufige Kommissionierung sowie manuelle Sortier-Kommissionierung sind möglich. Das System unterstützt Paletten- oder Einzelteilkommissionierung und Batch-Abwicklung. Als Sonderformen stehen Golden-Karton- und Umkartonkommissionierung zur Verfügung. Die Bereitstellungsformen ‘Pick-Pack’, ‘Mann zur Ware’ und ‘Ware zum Mann’ können dadurch mit einer höheren Effizienz abgebildet werden. Angepasste Prozesse für Aktionsware oder ‘Value Added Services’ sind ebenso Teil von TUP.WMS.

Steuerung

Über Avis- und Liefermonitoring werden Liefertermin, Mengen, Waren, Qualität, Unter- oder Überschreitungen überwacht. Das vereinfacht die Qualitätssicherung und Plausibilitätsprüfung in der Klärfallabwicklung.

Die Steuerung erfolgt durch die automatische oder manuelle Zielvergabe mit verschiedenen flexiblen und parametrierbaren Einlagerstrategien. Folgende Parameter finden dabei Anwendung: Logistische Stammdaten, physikalischen Parameter der Lagerplätze, Zuordung der Artikel zu Lagergruppen oder -zonen auf Basis von Priorisierungen wie ABC-Verteilung oder im Artikelstamm definierter Lagerstruktur. Für eine möglich granulare Kontrolle können Bereiche als Puffer oder mit einer Einlagersperre gekennzeichnet werden.

Das WMS generiert die Transportaufträge für den Materialflussrechner oder manuelle Prozess-Schritte. Es unterstützt über verschiedene Schnittstellen, wie beispielsweise WLAN, MDE-geführte Prozesse. Interne und externe Retouren werden ebenfalls über die Prozesssteuerung abgedeckt.

Labels und Dokumentation

Wareneingangsbelege jeglicher Art können automatisch oder manuell ausgedruckt werden: LE-, LTG-Labels, Barcodes, Einlagerhilfen oder Zollmeldungen.

Mehr Effizienz und Flexibilität für Ihren Warenausgang

Konsolidieren Sie Packstücke aus den unterschiedlichen Abläufen im Warenausgang, angepasst an Frachtführer, Ausgangsrelationen, Warenvielfalt und Cut-off-Zeit.

Konsolidierung

Über TUP.WMS können Sie Einzelsendungen parametergesteuert zusammenführen, die Waren eines Kundenauftrages zusammenstellen und die Aufträge nach Ländern, Versandart oder Touren clustern. Cross-Docking als effizienzsteigernde Maßnahme wird ebenfalls unterstützt.

Tourenbildung

Das System unterstützt Sie bei der Zusammenstellung von Touren und hilft Ihnen, die optimalen Volumina je nach Verladeart zu nutzen, beispielsweise über Paketdienste oder Speditionen.

Monitoring

Gewinnen Sie einen schnellen Überblick über die relevanten Kennzahlen Ihres Warenausgangs und verfolgen Sie Ihre Lieferungen über Tracking-Anbindungen nach dem Versand weiter.

Export und Zollabwicklung

Über TUP.WMS pflegen Sie Ihre Zolltarife und drucken die notwendigen Zollpapiere für Exportware. Für den Datentransfer an das Zollsystem sind ebenfalls Schnittstellen integriert.

Success Story

Grass GmbH central distribution center in Hohenems

TUP developed a customized Warehouse Management System (TUP.WMS) with an integrated Warehouse Control System (TUP.MFC).

Do you have any questions?