TUP.MES

Transform your system data into added value via interconnectivity

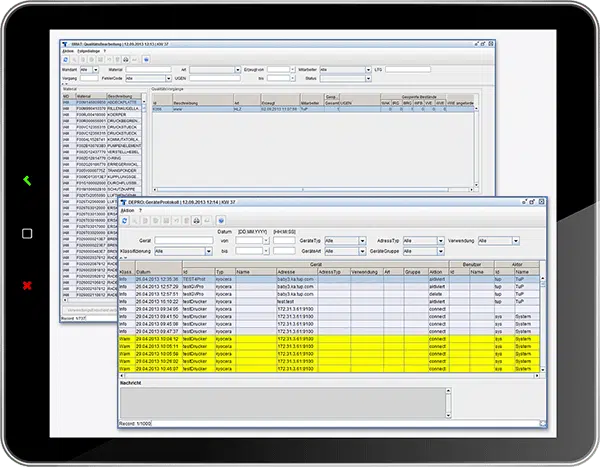

There are many parameters that can affect the performance of your internal processes. Only if your data is recorded accurately and efficiently the right decisions can be made. With TUP.MES and its straight-forward, transparent operation, the desired traceability in your processes is achieved.

software follows function

How the software manufactory principle creates high-quality data sets

The challenge in intralogistics is not to collect data, but to generate data in an understandable context in order to store them in a historically searchable and, above all, comparable manner. Standard solutions offer general key figures and dashboards in this respect, but they are not adapted to your business processes and therefore do not provide an ideal context. In comparison, the principle of software manufactory relies on market-proven standards, which we adapt to your needs in cooperation with you.

Our goal is to create a networked system landscape that enables manual or automatic data acquisition via mobile or stationary devices. This data must be transferred to your stored systems quickly, efficiently and in the correct form. With experience since 1980, we are experts in the structured processing of data, always with the aim of identifying optimization potential and simplifying day-to-day business.

The advantages

The advantages for your operating data collection

- A central system for operational data collection

- Straightforward collection of the process key figures

- Combination of manual and automated data collection

- Use of modern, mobile end devices

- Transparency in real-time processing

How we use operating data collection

In intralogistics, people complement the technical systems, but of course they do not behave as uniformly as a parcel sorter. That’s why we are developing coupled processes with buffers that enable employees to take their well-earned break. If the pick round is finished a little later, another process is not immediately affected.

The precise recording of data allows for a well-founded performance reward, as the actual performance is recorded on the basis of the relevant processes and not only on the basis of simple categories such as ‘start’ or ‘end’ of work. From this, calculation data can be derived for planning, controlling, cost accounting, performance comparisons, key figures, benchmarking and target agreements with the employee.

Overview of features - TUP.MES

Our solution for your operating data collection is the fuel for your connected systems, such as the ERP or WMS. Therefore, you need to rely on quality and individual customization.

An excerpt of the functions

- Browser-based dialogs for stationary and mobile devices

- Master data management

- Authorization control via assigning teams

- Support of group incentives

- Registration via personal barcode

- Collection of performance-related and non-performance-related activities

An extract of the interfaces

- Interfaces to upstream systems:

– Personnel Administration (ERP)– Logistics computer and sorter - Interfaces to downstream systems:

– Activity based cost accounting

– Performance based payroll accounting (ERP)

– Controlling

Your contact

You have a project enquiry or want individual consultation about TUP.MES?

Our sales manager Swen Weidenhammer is a specialist in combining automation solutions with modern information technology.